Wir haben festgestellt, dass Ihr Rechnungsort die USA ist.

Beachten Sie bitte, dass Ihre Rechnungsadresse mit der Adresse Ihres Einkaufsortes übereinstimmen muss. Wählen Sie eine der Optionen aus:

Neue Nutzungsbedingungen

Die Abonnementlaufzeit verlängert sich automatisch um weitere Abonnementlaufzeiten, es sei denn, eine Partei teilt der anderen mindestens 60 Tage vor dem Ende der jeweils aktuellen Abonnementlaufzeit mit, dass sie sich gegen eine Verlängerung entschieden hat. Jede verlängerte Abonnementlaufzeit hat die gleiche Länge wie die vorherige Laufzeit oder 12 Monate, je nachdem, welcher Zeitraum länger ist. Die Gebühren für jede verlängerte Abonnementlaufzeit entsprechen denen, die am Ende der vorhergehenden Abonnementlaufzeit gelten, es sei denn, Siemens teilt dem Kunden mindestens 90 Tage vor dem Ende der dann aktuellen Abonnementlaufzeit abweichende künftige Gebühren mit.

Das UCA (oder etwaige Nachfolgebedingungen), verfügbar unter Universal Customer Agreement (UCA), in der Fassung, die 60 Tage vor dem Ende der dann aktuellen Abonnementlaufzeit aktuell ist, gelten für die folgende Abonnementlaufzeit. Wenn Ihr Abonnement jedoch durch einen Rahmenvertrag geregelt ist, den Sie mit Siemens abgeschlossen haben, gilt dieser Rahmenvertrag weiterhin für alle folgenden Abonnementlaufzeiten, und die in diesem Rahmenvertrag vereinbarten Bedingungen für die automatische Verlängerung des Abonnements haben Vorrang.

In allen Fällen gelten anstelle etwaiger früherer Versionen der Ergänzenden Bedingungen die unter Ergänzende Bedingungen verfügbaren anwendbaren Ergänzenden Bedingungen in der jeweils 60 Tage vor Ablauf des jeweiligen Zeitraums aktuellen Version.

Zusätzliche Geschäftsbedingungen, die im ursprünglichen Bestellformular vereinbart wurden (einschließlich der Ergänzenden Bedingungen) sowie vereinbarte Zahlungsbedingungen, bleiben für alle folgenden Abonnementlaufzeiten in Kraft.

Prerequisites

Industrial Edge for Machine Tools sales BOM

Product ID

MCS2051

Additional Information

Industrial Edge for Machine Tools Package

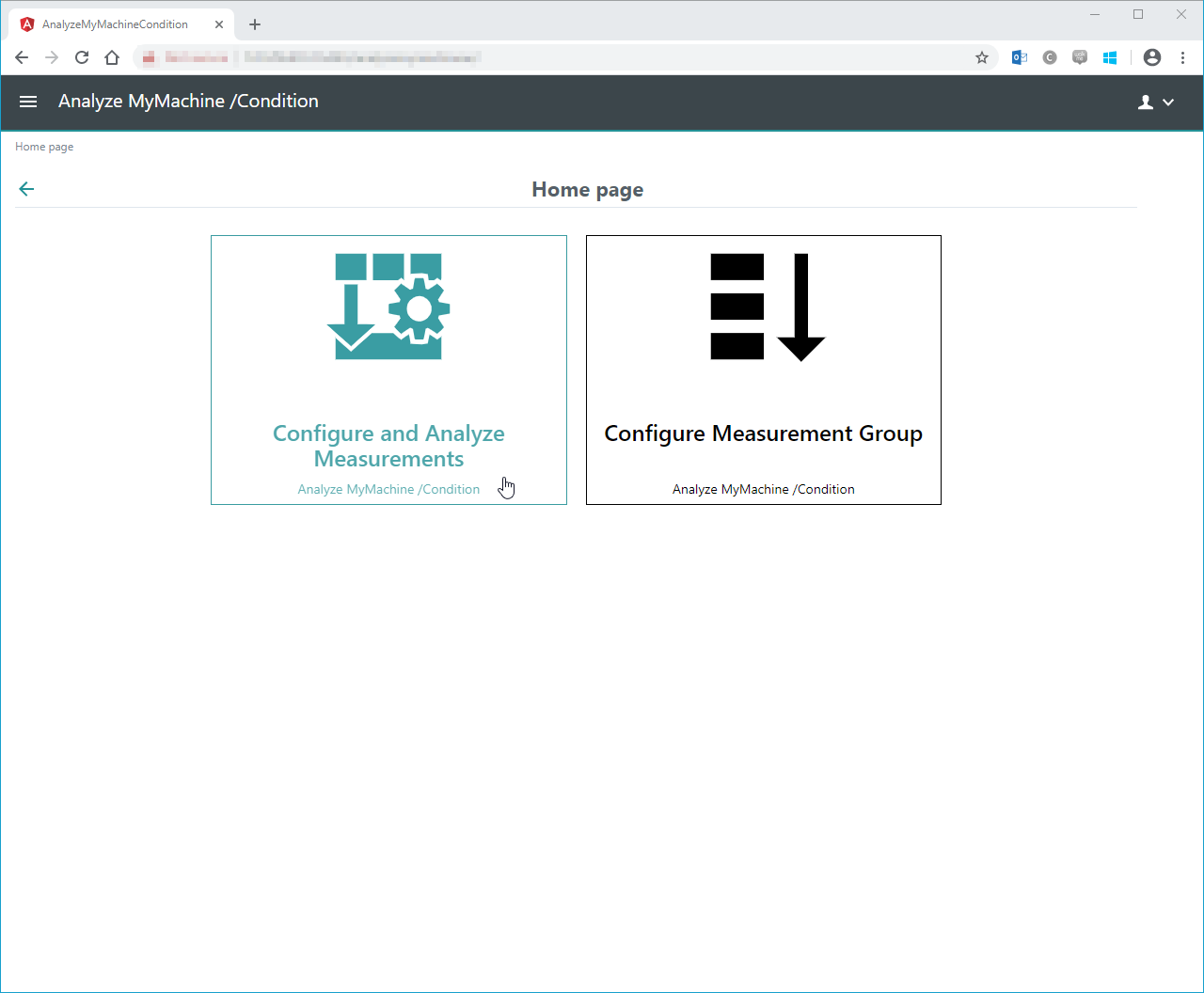

Analyze MyMachine /Condition - (Edge only)

Bereitgestellt von SIEMENS

Increase a machine tool's availability by tracking its condition with a mechanical fingerprint.

The hybrid Industrial Edge for Machine Tools Analyze MyMachine /Condition enables users to generate a machine tool's mechanical fingerprint so that potential deviations can be identified at an early stage, machine failures prevented and machine operation optimized.

Following characteristics of a drive train can be measured via Edge App:

- Equability

- Friction

- Backlash

- Signature

- Quadrant error

- Stiffness

- Frequency response

| Pricing Breakdown per Device | One Time | Annually |

|---|---|---|

| License | €4.200,00 | |

| Maintenance | €924,00 | €924,00 |

| Total Initial Price | €8.484,00 |