Hemos detectado que tu ubicación de facturación es Estados Unidos.

Tu dirección de facturación debe estar en el mismo país que tu lugar de compra. Selecciona una de las opciones:

Nuevos términos de uso

El Plazo de suscripción se renovará automáticamente para los Plazos de suscripción sucesivos, a menos que una de las partes notifique a la otra, con una antelación mínima de 60 días antes de que finalice el Plazo de suscripción vigente, que ha optado por no renovarlo. Cualquier Plazo de suscripción renovado tendrá la misma duración que el plazo anterior o 12 meses, lo que sea mayor. Las tarifas para cualquier Plazo de suscripción renovado serán las mismas que estén en vigor al finalizar el Plazo de suscripción anterior, a menos que Siemens notifique al Cliente la aplicación de tarifas futuras diferentes como mínimo 90 días antes de que finalice el Plazo de suscripción vigente en ese momento.

El UCA (o cualquier término sucesor) disponible en Acuerdo Universal de Clientes (UCA) en la versión vigente 60 días antes del final del Plazo de suscripción que esté en vigor se aplicará al siguiente Plazo de suscripción. Sin embargo, si su suscripción se rige por un acuerdo marco que haya firmado con Siemens, dicho contrato marco seguirá siendo de aplicación para cualquier Plazo de suscripción siguiente, y prevalecerán las condiciones de renovación automática de la suscripción especificadas en dicho acuerdo marco.

En todos los casos, en lugar de cualquier versión anterior de los Términos complementarios, se aplicarán para el siguiente Plazo de suscripción los correspondientes Términos complementarios disponibles en Términos complementarios en la versión vigente 60 días antes del final del Plazo de suscripción que esté en vigor.

Los términos y condiciones adicionales acordados en el formulario de pedidos inicial (incluidas las condiciones del producto), así como las condiciones de pago acordadas, seguirán en vigor para cualquier Periodo de suscripción siguiente.

Prerequisites

Industrial Edge for Machine Tools sales BOM

Product ID

MCS2051

Additional Information

Industrial Edge for Machine Tools Package

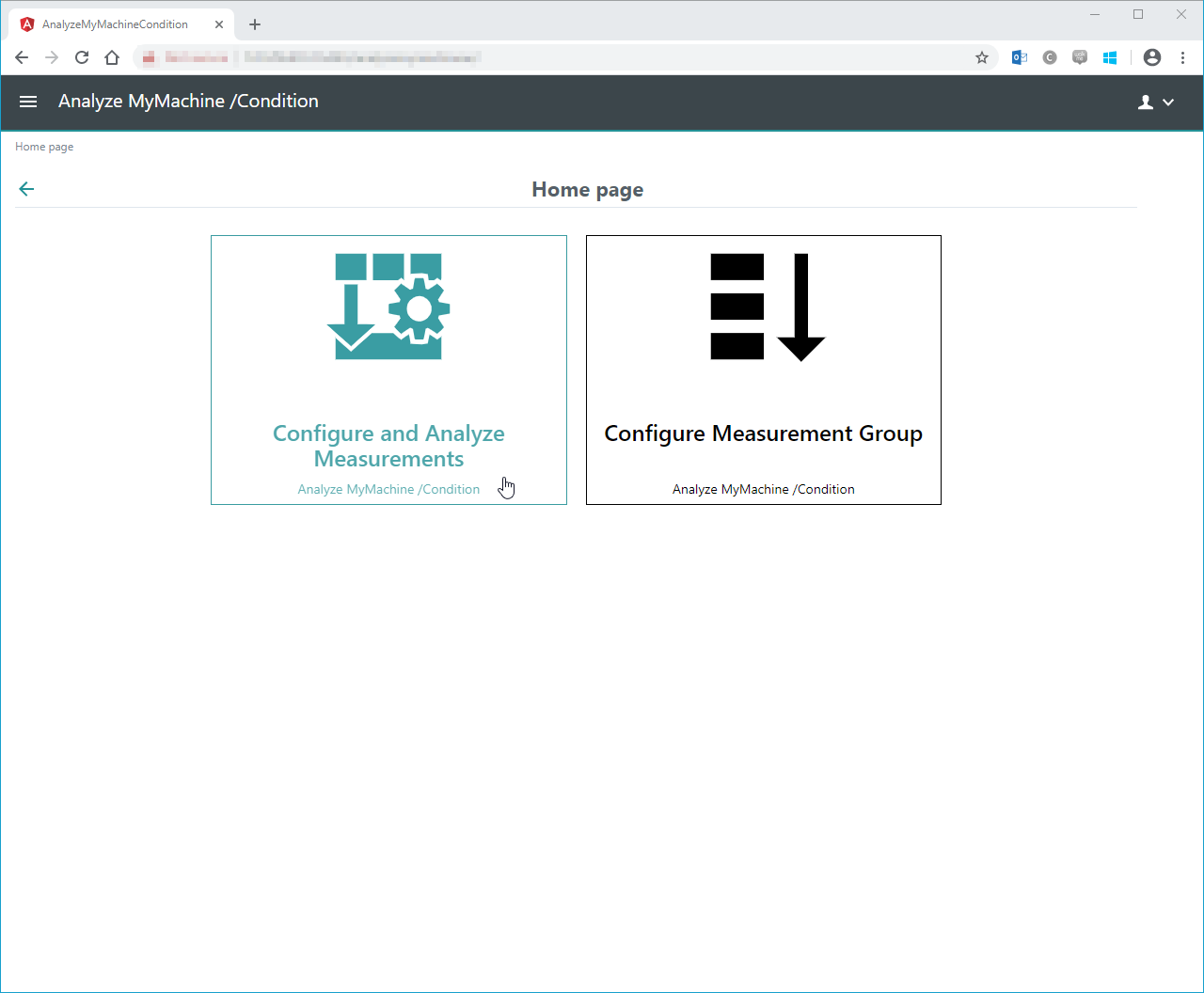

Analyze MyMachine /Condition - (Edge only)

Operado por SIEMENS

Increase a machine tool's availability by tracking its condition with a mechanical fingerprint.

The hybrid Industrial Edge for Machine Tools Analyze MyMachine /Condition enables users to generate a machine tool's mechanical fingerprint so that potential deviations can be identified at an early stage, machine failures prevented and machine operation optimized.

Following characteristics of a drive train can be measured via Edge App:

- Equability

- Friction

- Backlash

- Signature

- Quadrant error

- Stiffness

- Frequency response

| Pricing Breakdown per Device | One Time | Annually |

|---|---|---|

| License | €4.200,00 | |

| Maintenance | €924,00 | €924,00 |

| Total Initial Price | €8.484,00 |