我们注意到您的账单地址是在美国

请注意,您的帐单地址应与购买地点位于同一国家/地区。请选择以下选项之一:

新增使用条款

订阅期将自动在后续订阅期内续订,除非任何一方在相关订阅期满前至少提前 60 天通知另一方不再续订。任何续订的订阅期将与前一订阅期期限相同或为 12 个月(以较长者为准)。任何续订期的费用将与前一订阅期结束时施行的费用相同,除非西门子在相关订阅期满前至少提前 90 天通知客户未来费用变化。

通用客户协议 (UCA) 中提供的 UCA(或任何后续条款)在当时的订阅期限结束前 60 天的当前版本将适用于下一个订阅期。但是,如果订阅受您与西门子签署的主协议的约束,则该主协议将继续适用于任何后续订阅期,并且该主协议中指定的订阅的自动续订条款将适用。

在所有情况下,补充条款中提供的适用补充条款(在当时的订阅期限结束前 60 天的当前版本)将适用于下一个订阅期限,而不是补充条款的任何先前版本。

初始订购单中商定的附加条款和条件(包括产品特定条款)以及商定的付款条款将在以后的任何订阅期限内保持有效。

-sinumerik-840d-sl/mcs2043n.png)

Product ID

MCS2043N

Additional Requirements

Desktop computer with dedicated grapics and a full HD display

Discover More

Click here to learn more

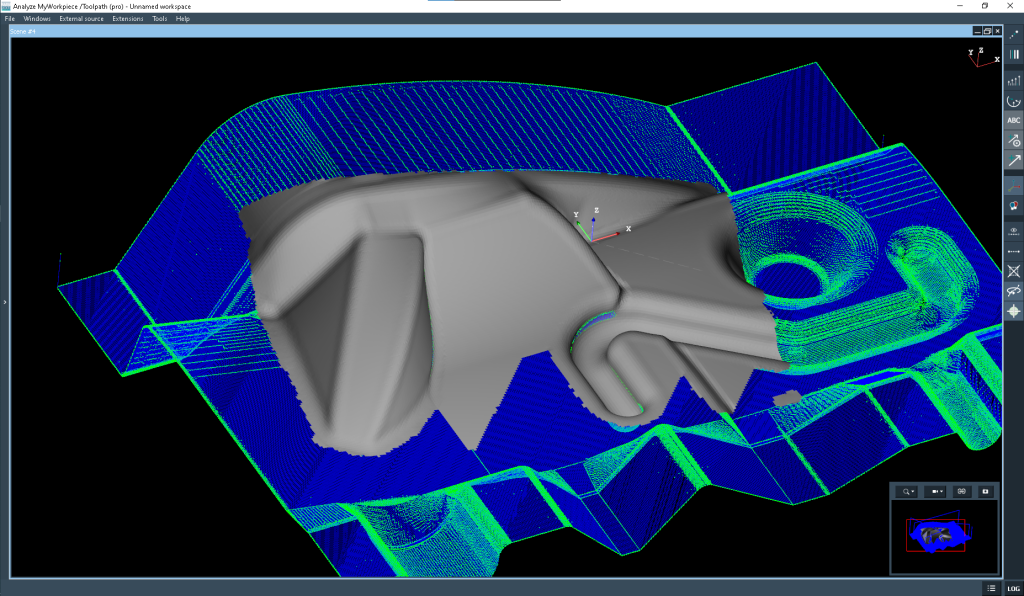

Analyze MyWorkpiece/Toolpath Node Locked

提供商: SIEMENS

G-Code verification and visual process analysis to ensure optimal quality and productivity

Analyze MyWorkpiece /Toolpath is a powerful aid to optimize speed and quality of manufacturing processes that involve complex motion. This not only comprises subtractive machining but also 3D printing and robotic applications. It features intuitive graphical 3D inspection methods that are key to identify disturbances in the CAD-CAM-CNC process chain and the respective improvement potentials.

The application can be used for upfront G-Code verification but also allows to pin-point root causes of poor process performance by analyzing high frequency data recorded using the Industrial Edge for Machine Tools.