Wir haben festgestellt, dass Ihr Rechnungsort die USA ist.

Beachten Sie bitte, dass Ihre Rechnungsadresse mit der Adresse Ihres Einkaufsortes übereinstimmen muss. Wählen Sie eine der Optionen aus:

Neue Nutzungsbedingungen

Die Abonnementlaufzeit verlängert sich automatisch um weitere Abonnementlaufzeiten, es sei denn, eine Partei teilt der anderen mindestens 60 Tage vor dem Ende der jeweils aktuellen Abonnementlaufzeit mit, dass sie sich gegen eine Verlängerung entschieden hat. Jede verlängerte Abonnementlaufzeit hat die gleiche Länge wie die vorherige Laufzeit oder 12 Monate, je nachdem, welcher Zeitraum länger ist. Die Gebühren für jede verlängerte Abonnementlaufzeit entsprechen denen, die am Ende der vorhergehenden Abonnementlaufzeit gelten, es sei denn, Siemens teilt dem Kunden mindestens 90 Tage vor dem Ende der dann aktuellen Abonnementlaufzeit abweichende künftige Gebühren mit.

Das UCA (oder etwaige Nachfolgebedingungen), verfügbar unter Universal Customer Agreement (UCA), in der Fassung, die 60 Tage vor dem Ende der dann aktuellen Abonnementlaufzeit aktuell ist, gelten für die folgende Abonnementlaufzeit. Wenn Ihr Abonnement jedoch durch einen Rahmenvertrag geregelt ist, den Sie mit Siemens abgeschlossen haben, gilt dieser Rahmenvertrag weiterhin für alle folgenden Abonnementlaufzeiten, und die in diesem Rahmenvertrag vereinbarten Bedingungen für die automatische Verlängerung des Abonnements haben Vorrang.

In allen Fällen gelten anstelle etwaiger früherer Versionen der Ergänzenden Bedingungen die unter Ergänzende Bedingungen verfügbaren anwendbaren Ergänzenden Bedingungen in der jeweils 60 Tage vor Ablauf des jeweiligen Zeitraums aktuellen Version.

Zusätzliche Geschäftsbedingungen, die im ursprünglichen Bestellformular vereinbart wurden (einschließlich der Ergänzenden Bedingungen) sowie vereinbarte Zahlungsbedingungen, bleiben für alle folgenden Abonnementlaufzeiten in Kraft.

-sinumerik-840d-sl/mcs11000-product.jpg)

Product ID

MCS2043p

Discover More

Click here to learn more

Additional Requirements

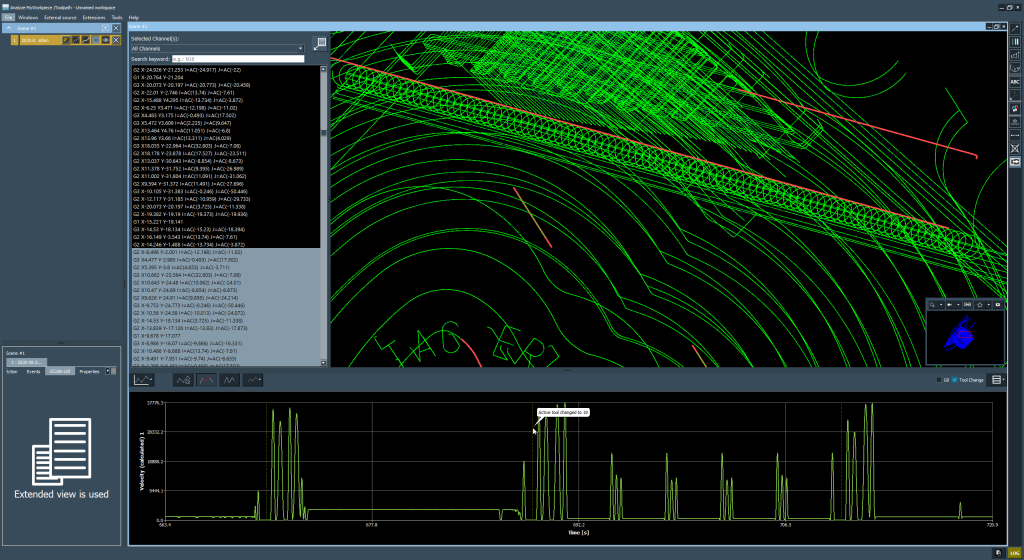

Desktop computer with dedicated grapics and a full HD display, A license of Analyze MyWorkpiece /Toolpath (MCS2043)

Analyze MyWorkpiece /Toolpath pro (floating license)

Bereitgestellt von SIEMENS

Increase speed and quality of your manufacturing process by means of data visualization and analytics

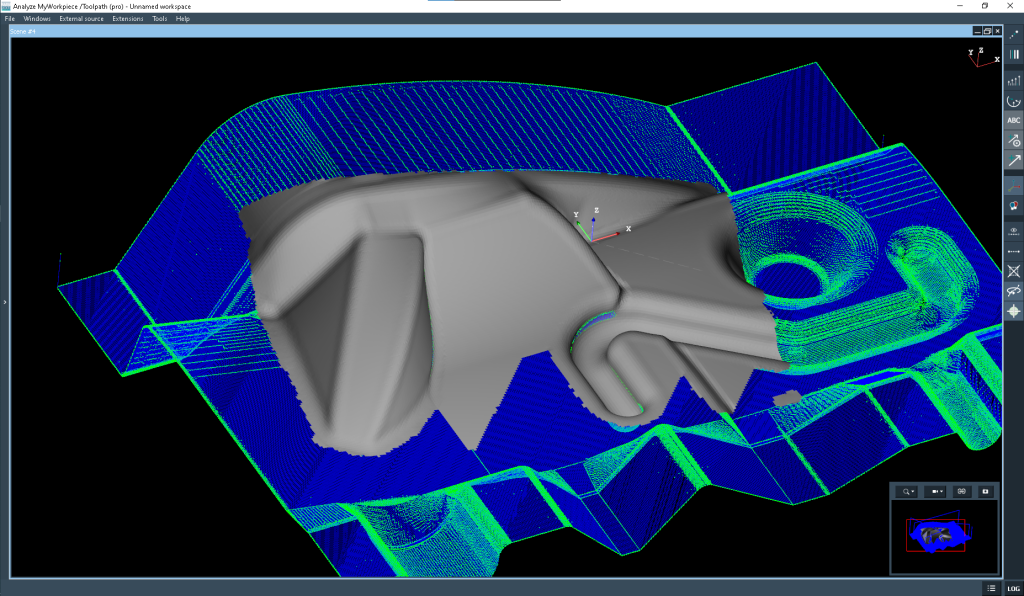

Analyze MyWorkpiece /Toolpath is a powerful aid to optimize speed and quality of manufacturing processes that involve complex motion. This not only comprises subtractive machining but also 3D printing and robotic applications. It offers efficient 3D inspection tools to visualize and analyze NC programs, data collected with SINUMERIK Operator trace or Analyze MyWorkpiece /Capture and also generic csv files.

Sophisticated grapical methods such as color coding process data on the toolpath in 3D are key to indentify disturbances in the CNC process chain and respective potentials for improvement.