請求先住所が米国になっています。

請求先住所と購入住所は同じでなければなりません。次のオプションから1つ選択してください。

新しい利用規約

いずれかの当事者が、その時点のサブスクリプション期間終了の 60 日前までに更新しないことを相手方に通知しない限り、サブスクリプション期間は、連続するサブスクリプション期間について自動的に更新されます。更新されたサブスクリプション期間は、直前の契約期間と同じ長さ、または 12 か月のいずれか長い方となります。更新されたサブスクリプション期間の料金は、シーメンスが、その時点のサブスクリプション期間終了の 90 日前までに将来の料金についてお客様に通知しない限り、直前のサブスクリプション期間終了時に有効であった料金と同じになります。

サブスクリプション期間終了の 60 日前に、Universal Customer Agreement (UCA) において最新バージョンで利用可能な UCA (またはその後継条件) が、次のサブスクリプション期間に適用されます。ただし、お客様のサブスクリプションがシーメンスと既に締結したマスター契約によって規定されている場合、当該マスター契約が、次のサブスクリプション期間にも引き続き適用され、当該マスター契約で規定されるサブスクリプションの自動更新条件が優先されるものとします。

すべての場合において、旧バージョンの補足条件の代わりに、その時点の補足条件の終了の 60 日前に補足条件において最新バージョンで利用可能な補足条件が次のサブスクリプション期間に適用されます。

最初のオーダーフォームで合意された追加の条件 (製品固有条項を含む) および合意された支払い条件は、次のサブスクリプション期間中も有効となります。」

-sinumerik-840d-sl/mcs11000-product.jpg)

Product ID

MCS2043p

Discover More

Click here to learn more

Additional Requirements

Desktop computer with dedicated grapics and a full HD display, A license of Analyze MyWorkpiece /Toolpath (MCS2043)

Analyze MyWorkpiece /Toolpath pro (floating license)

提供: SIEMENS

Increase speed and quality of your manufacturing process by means of data visualization and analytics

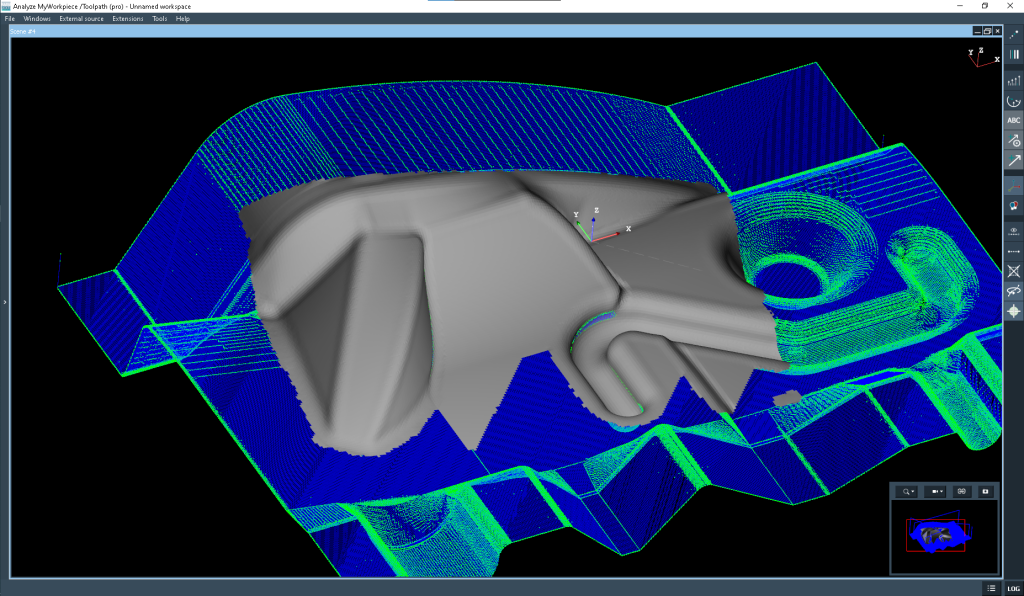

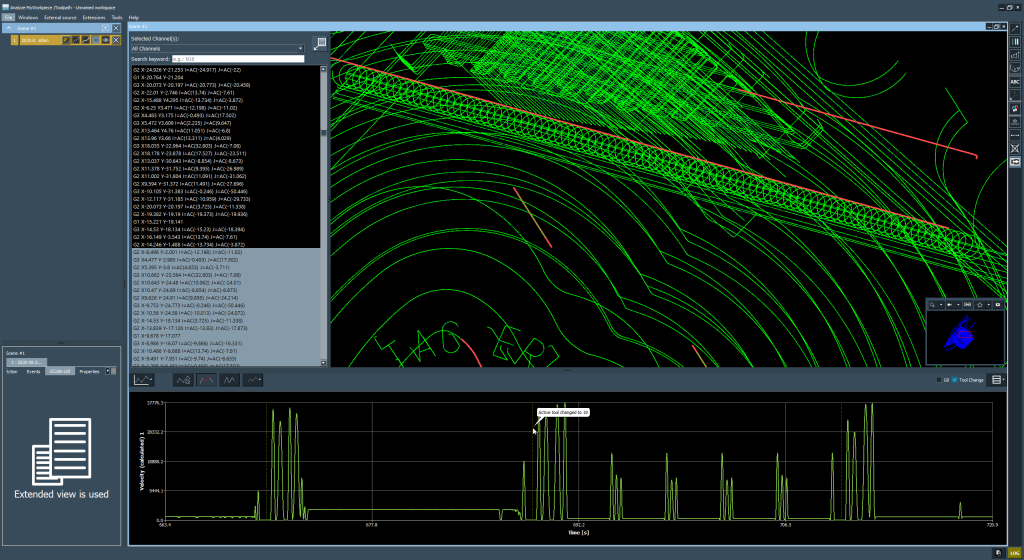

Analyze MyWorkpiece /Toolpath is a powerful aid to optimize speed and quality of manufacturing processes that involve complex motion. This not only comprises subtractive machining but also 3D printing and robotic applications. It offers efficient 3D inspection tools to visualize and analyze NC programs, data collected with SINUMERIK Operator trace or Analyze MyWorkpiece /Capture and also generic csv files.

Sophisticated grapical methods such as color coding process data on the toolpath in 3D are key to indentify disturbances in the CNC process chain and respective potentials for improvement.