We realized that your billing location is USA.

Please note that your billing address should be in the same country as your buying location. Please select one of the options:

Nouvelles Conditions d’Utilisation

La Période d'abonnement sera automatiquement renouvelée pour des Périodes d'abonnement successives, à moins que l'une des parties ne notifie à l'autre qu'elle a choisi de ne pas renouveler son abonnement au moins 60 jours avant la fin de la Période d'abonnement en cours. Toute Période d'abonnement renouvelée sera de la même durée que la période précédente, ou de 12 mois, la durée la plus longue des deux étant retenue. Les frais dus pour toute Période d'abonnement renouvelée sont les mêmes que ceux en vigueur à la fin de la Période d'abonnement précédente, à moins que Siemens n'informe le Client de la modification future desdits frais au moins 90 jours avant la fin de la Période d'abonnement en cours.

L'UCA (ou tout contrat qui lui succéderait) disponible sur la page Contrat client universel (UCA), dans sa version en vigueur 60 jours avant l'expiration de la Période d'abonnement en cours, s'appliquera à la Période d'abonnement suivante. Cependant, si votre abonnement est soumis à un contrat-cadre que vous avez conclu avec Siemens, ce contrat-cadre restera en vigueur pour toute Période d'abonnement ultérieure. Dans ce cas, les modalités de renouvellement automatique de l'abonnement stipulées dans le contrat-cadre prévaudront. Dans tous les cas, ce sont les Conditions supplémentaires en vigueur 60 jours avant l'expiration de la Période d'abonnement actuelle qui s'appliqueront à la Période d'abonnement suivante, et non les versions antérieures. Ces Conditions supplémentaires sont consultables sur la page Conditions supplémentaires.

Product ID

MCS2043PN

Additional Requirements

Desktop computer with dedicated grapics and a full HD display

Discover More

Click here to learn more

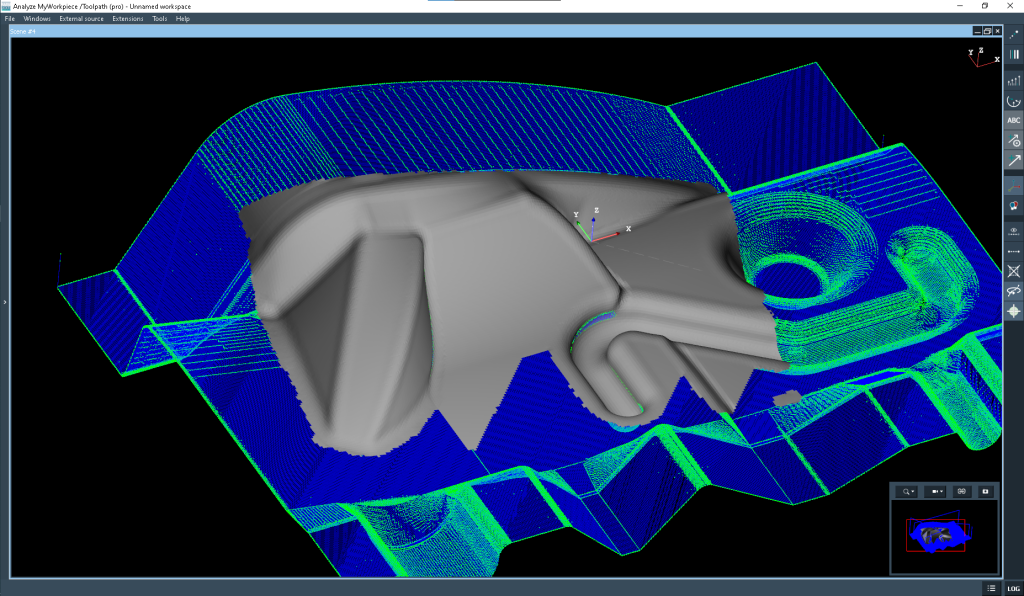

Analyze MyWorkpiece/Toolpath pro Node Locked

Fourni par SIEMENS

Advanced analysis features for Analyze MyWorkpiece /Toolpath

Analyze MyWorkpiece /Toolpath (pro) is an extension package for Analyze MyWorkpiece /Toolpath that adds advanced features targeted at in-depth process analysis and machine tool commissioning.