We realized that your billing location is USA.

Please note that your billing address should be in the same country as your buying location. Please select one of the options:

New Terms of Use

The Subscription Term will automatically renew for successive Subscription Terms unless either party notifies the other at least 60 days prior to the end of the then-current Subscription Term that it has elected not to renew. Any renewed Subscription Term will be the same length as the preceding term or 12 months, whichever is greater. The fees for any renewed Subscription Term will be the same as those in effect at the end of the preceding Subscription Term, unless Siemens notifies Customer about different future fees at least 90 days prior to the end of the then-current Subscription Term.

The UCA (or any successor terms) available at Universal Customer Agreement (UCA) in the version that is current 60 days prior to the end of the then-current Subscription Term will apply for the following Subscription Term. However, if your subscription is governed by a master agreement that you have executed with Siemens, then that master agreement will continue to apply for any following Subscription Term, and auto-renewal terms for the subscription specified in that master agreement will prevail.

In all cases, instead of any previous versions of Supplemental Terms, the applicable Supplemental Terms available at Supplemental Terms in the version that is current 60 days prior to the end of the then-current Subscription Term will apply for the following Subscription Term.

Additional terms and conditions agreed upon in the initial order form (including product-specific terms), as well as agreed payment terms, will remain in effect for any following Subscription Term.

Prerequisites

Industrial Edge for Machine Tools sales BOM

Product ID

MCS2051

Additional Information

Industrial Edge for Machine Tools Package

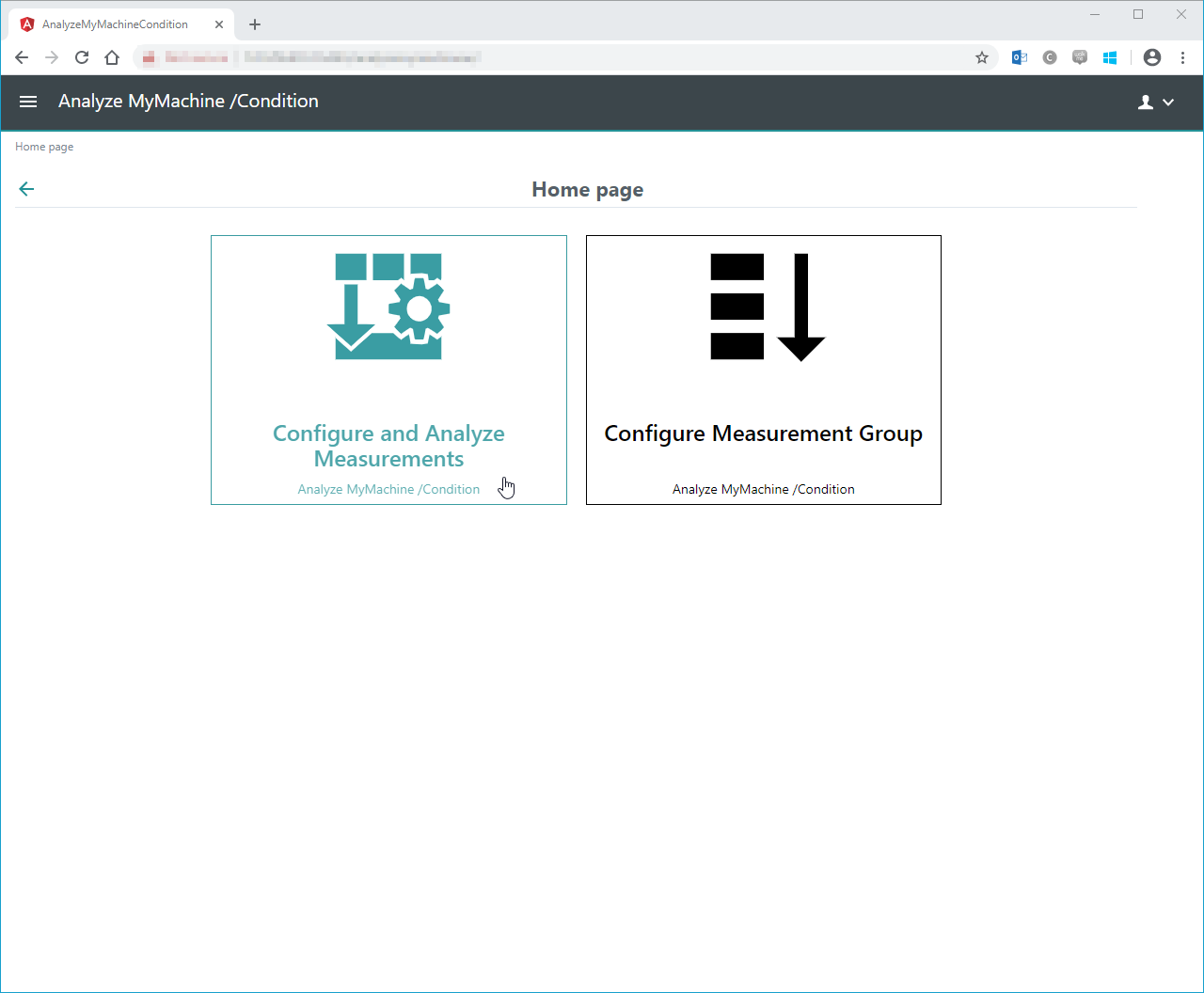

Analyze MyMachine /Condition - (Edge only)

Provided by SIEMENS

Increase a machine tool's availability by tracking its condition with a mechanical fingerprint.

The hybrid Industrial Edge for Machine Tools Analyze MyMachine /Condition enables users to generate a machine tool's mechanical fingerprint so that potential deviations can be identified at an early stage, machine failures prevented and machine operation optimized.

Following characteristics of a drive train can be measured via Edge App:

- Equability

- Friction

- Backlash

- Signature

- Quadrant error

- Stiffness

- Frequency response

Offering Overview

| Pricing Breakdown per Device | One Time | Annually |

|---|---|---|

| License | €4.000,00 | |

| Maintenance | €881,00 | €881,00 |

| Total Initial Price | €4.881,00 |