We realized that your billing location is USA.

Please note that your billing address should be in the same country as your buying location. Please select one of the options:

New Terms of Use

The Subscription Term will automatically renew for successive Subscription Terms unless either party notifies the other at least 60 days prior to the end of the then-current Subscription Term that it has elected not to renew. Any renewed Subscription Term will be the same length as the preceding term or 12 months, whichever is greater. The fees for any renewed Subscription Term will be the same as those in effect at the end of the preceding Subscription Term, unless Siemens notifies Customer about different future fees at least 90 days prior to the end of the then-current Subscription Term.

The UCA (or any successor terms) available at Universal Customer Agreement (UCA) in the version that is current 60 days prior to the end of the then-current Subscription Term will apply for the following Subscription Term. However, if your subscription is governed by a master agreement that you have executed with Siemens, then that master agreement will continue to apply for any following Subscription Term, and auto-renewal terms for the subscription specified in that master agreement will prevail.

In all cases, instead of any previous versions of Supplemental Terms, the applicable Supplemental Terms available at Supplemental Terms in the version that is current 60 days prior to the end of the then-current Subscription Term will apply for the following Subscription Term.

Additional terms and conditions agreed upon in the initial order form (including product-specific terms), as well as agreed payment terms, will remain in effect for any following Subscription Term.

-sinumerik-840d-sl/mcs11000-product.jpg)

Additional Requirements

Desktop computer with dedicated grapics and a full HD display

Discover More

Click here to learn more

Product ID

MCS2043

Analyze MyWorkpiece /Toolpath (floating license)

Provided by SIEMENS

G-Code verification and process analysis to ensure optimal workpiece quality and productivity

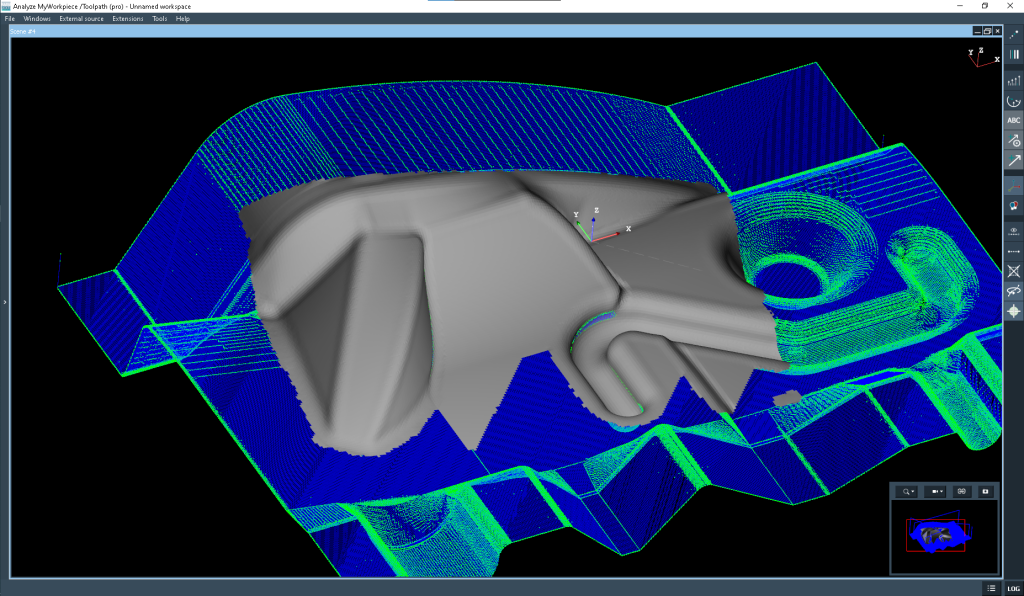

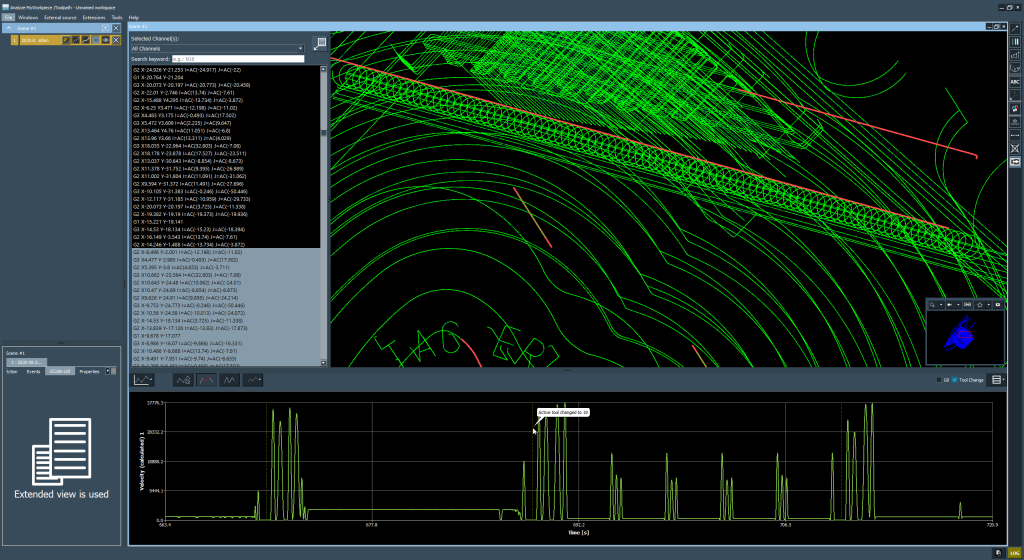

Analyze MyWorkpiece /Toolpath is a powerful aid to optimize speed and quality of manufacturing processes that involve complex motion. This not only comprises subtractive machining but also 3D printing and robotic applications. It features intuitive graphical 3D inspection methods that are key to identify disturbances in the CAD-CAM-CNC process chain and the respective improvement potentials.

The application can be used for upfront G-Code verification but also allows to pin-point root causes of poor process performance by analyzing high frequency data recorded using the Industrial Edge for Machine Tools.