We realized that your billing location is USA.

Please note that your billing address should be in the same country as your buying location. Please select one of the options:

New Terms of Use

The Subscription Term will automatically renew for successive Subscription Terms unless either party notifies the other at least 60 days prior to the end of the then-current Subscription Term that it has elected not to renew. Any renewed Subscription Term will be the same length as the preceding term or 12 months, whichever is greater. The fees for any renewed Subscription Term will be the same as those in effect at the end of the preceding Subscription Term, unless Siemens notifies Customer about different future fees at least 90 days prior to the end of the then-current Subscription Term.

The UCA (or any successor terms) available at Universal Customer Agreement (UCA) in the version that is current 60 days prior to the end of the then-current Subscription Term will apply for the following Subscription Term. However, if your subscription is governed by a master agreement that you have executed with Siemens, then that master agreement will continue to apply for any following Subscription Term, and auto-renewal terms for the subscription specified in that master agreement will prevail.

In all cases, instead of any previous versions of Supplemental Terms, the applicable Supplemental Terms available at Supplemental Terms in the version that is current 60 days prior to the end of the then-current Subscription Term will apply for the following Subscription Term.

Additional terms and conditions agreed upon in the initial order form (including product-specific terms), as well as agreed payment terms, will remain in effect for any following Subscription Term.

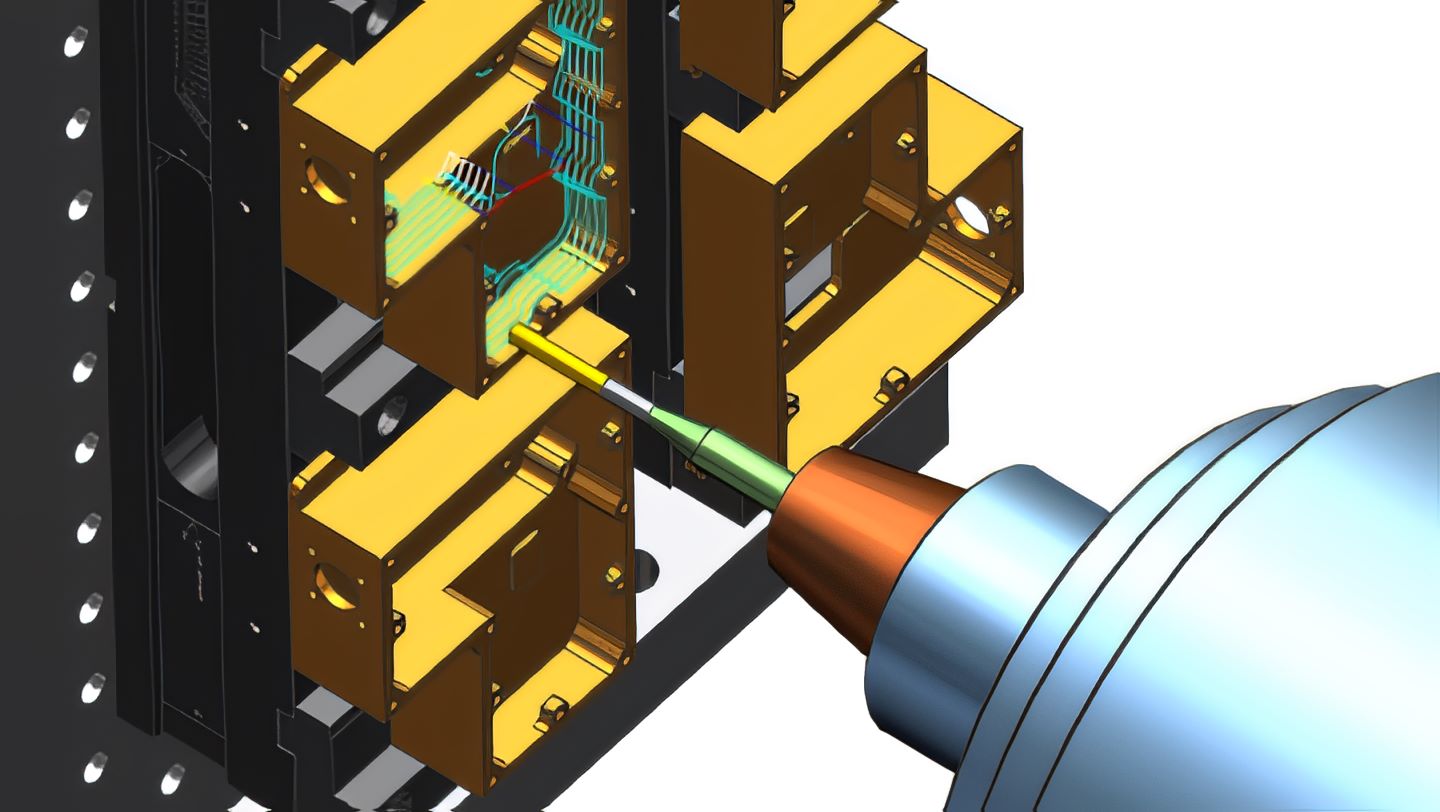

NX CAD/CAM Multi-Axis Mill-Turn XaaS

Provided by SIEMENS

Core package for general milling and turning with expanded modeling functions

Increase your productivity using powerful capabilities to program a wide range of CNC milling and lathe machine configurations.

2.5-Axis Milling

Automate programming of prismatic parts using advanced capabilities, including:

- Volume-based milling

- Automated hole-making

- Feature-based machining

- In-process Workpiece (IPW) material tracking

Turning

Quickly program single or dual chucks lathes using a range of turning operations, such as:

- Efficient roughing

- Multiple-pass finishing and facing

- Thread cutting

- Centerline drilling

Integrated CAD

Quickly create optimized and collision-free toolpaths using the integrated CAD capabilities, including:

- Synchronous Technology for part model preparation

- Solid modeling for parts, fixtures and workholding design

- Assembly functions for machine setup modeling

Generate validated production-ready NC programs, using the integrated post-processor and machining simulation capabilities. Digitally connect planning and production with associative shop documentation, including tool lists and setup sheets.

Teamcenter Share: Cloud-based collaboration

Your subscription also includes access to Teamcenter Share, a next-generation, cloud-based collaboration solution from Siemens. With capabilities including secure, central storage and e-mail address-based sharing, Teamcenter Share allows you to instantly, securely and easily collaborate with colleagues, partners and customers. An Enterprise Cloud Account (ECA) will be provided to you for administrators to gain access to Teamcenter Share and delegate additional privileges.

For Teamcenter Share cloud services, a limitation of 10 Authorized Users (including guest users) per collaboration project applies, unless Customer has purchased additional entitlements. Any volume of storage space noted above for Teamcenter Share is incremental to the floating storage of 500 GB available for use across all of Customer's current subscriptions which include Teamcenter Share cloud services and which are assigned to the same tenant. Numbers noted above for Authorized Users and storage for Teamcenter Share are not listed on a per quantity basis.

Except guest users, all Authorized Users of Teamcenter Share cloud services will receive access to "Getting Started with Siemens Xcelerator Academy" (LAAS49000) on-demand training on the Siemens Xcelerator Academy portal.